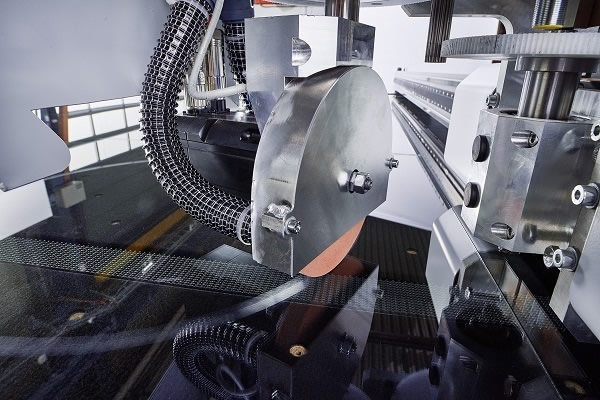

The result speaks for itself: The brand new high-performance machine in the new LiSEC design with the name SprintCut cuts flat glass automatically and quickly thanks to the state-of-the-art motive power engineering.

LiSEC SprintCut: maximise speed and sprint to success

Linear motive power engineering as the secret of success

With linear motive power engineering and the integrated measuring system, the new SprintCut ensures maximum cutting speed and outstanding dynamics. The maximum acceleration is approx. 16 m/s² and the maximum speed 310 m/min.

"Our linear drive has few moving parts, which means the mechanical wear is lower, resulting in longer maintenance intervals and low downtime costs", says Thomas Traugott, Head of Business Unit Glass Cutting at LiSEC.

Besides the especially high acceleration, this motive power engineering allows an excellent positioning accuracy of the cutting head with a maximum offset of 0.1 mm. Due to the intelligent control, the maximum speed is reached as quickly as possible.

Traugott continues: "Through careful constructive improvements, we were able to significantly reduce the noise emissions and optimise the handling of the entire machine even more, a benefit for every operator and machine operating company."

Measuring system ensures the necessary precision

The operation of the cutting table is made easier by an even higher degree of automation and new electronic controls.

The cutting pressure control, grinding pressure control, the monitoring of the consumption of cutting oil and cutting wheel wear are automated and, as a preventive measure, the control system indicates pending replacements or fillings, thus reducing unplanned downtimes.

“The new machine sets a high standard in its class in relation to price/performance. Especially customers with highly automated production lines in multiple-shift operation can benefit from up to 20% shorter cycle times", explains Thomas Traugott.

You are not logged in, please sign in to view contact

You are not logged in, please sign in to view contact Info release

Info release Promotion

Promotion Building shop

Building shop Online business

Online business